Coating Cleaning Machine

The design, selection, manufacturing, inspection, and testing of this equipment are carried out in accordance with relevant national and semiconductor industry standards (SEMI-S2-93)

1.1 Equipment Overview

The main function is to clean the components, and this equipment has a good cleaning process;

Basic parameter table of equipment

|

Equipment name |

Coating cleaning machine |

|

|

Equipment number |

KSXRW-TBQXJ10-01 |

|

|

quantity |

1 unit |

|

|

Equipment size |

3500mm(L)×1200mm(W)×1900mm(H) |

|

|

Cleaning product size |

600mm × 280mm roll material |

|

|

Loading and unloading materials |

hand movement |

|

|

process control |

PLC control |

|

|

TOUCH SCREEN CONTROLLER |

||

|

Liquid inlet control |

Manual liquid preparation |

|

|

DIRECTION |

Machine direction |

Left in and right out |

|

Mechanical arm bearing |

Capacity |

Max.5-10Kg/time |

|

Quantity of workpieces |

One roll/time |

|

|

Dual protection for dry burning hardware and software |

not have |

|

|

Liquid level protection function |

have |

|

|

Temperature protection function |

not have |

|

|

Leakage detection function |

have |

|

|

Time setting |

0-12 hours can be set (depending on the actual process time) |

|

|

Capacity design |

Two shift system (note: working 24H/day, 360 days/year) |

|

|

Equipment stability |

UPTIME: UPTIME ≥ 98% (1- (fault time+PM time)/total time) |

|

|

MTTR: MTTR ≤ 4h (MTTR=total repair time/total number of failures) |

||

|

MTBE: MTBE ≥ 450h (MTBF=total operating time/total number of failures) |

||

|

Equipment operating temperature range |

20-25°C |

|

|

relative humidity |

<70% |

|

1.2 Equipment Features

|

standard |

The design, selection, manufacturing, inspection, and testing of this equipment are carried out in accordance with relevant national and semiconductor industry standards (SEMI-S2-93), standardized and guaranteed by the ISO9001 quality management system, except as otherwise specified in the contract or technical documents.The purchased accessories shall comply with the corresponding national standards, industry standards, specifications, and enterprise standards |

|

The equipment includes |

Equipment body, electrical control part, chemical process tank, etc;And provide interfaces that are compatible with the factory's power supply, gas supply, water supply, wastewater discharge, exhaust system, etc |

|

main body |

The main body of the equipment is made of domestic porcelain white 10mm PP board, which is sturdy and durable, with double-layer leak proof, |

|

Skeleton |

SUS304+PP domestic porcelain whiteboard combination to prevent rusting of the shell |

|

safety door |

Installation of equipment with left and right movable transparent PVC doors to separate and protect personnel safety (convenient for observing and cleaning processes) |

|

Process tank |

Modular design, with the corrosion tank and pure water flushing tank placed in a unified leak proof chassis.The chassis is processed using full welding technology to eliminate the risk of machine leakage (no black spots, no dead corners or foreign objects) (equipped with a separate liquid discharge pipeline) |

|

pipe system |

Located at the bottom of the equipment, all process tanks, pipelines, and valve parts are clearly labeled;PFA pipes are used for the liquid medicine pipeline, PFA pipes are used for the pure water pipeline, and the chemical corrosion tank waste liquid and flushing wastewater are discharged through dedicated pipelines |

|

electrical protection |

The electrical control, gas path control, and process tank control sections are located in a separate electrical control area at the rear of the equipment. The electrical components are adequately protected against acid mist corrosion to ensure stable and reliable equipment performance and operation; |

|

Machine support legs |

There are pulley devices and fixing devices with anti-corrosion seats, and they have height adjustment and locking functions |

|

security guarantee |

Complete alarm and protection design, hardware or software interlocking for exhaust pressure, liquid level, and drainage, intuitive operation interface, clear information prompts, ensuring production, process control, and safety. Three color warning lights are placed prominently above the machine (with equipment emergency stop function) |

2. Process flow and process details

2.1 Process flow:

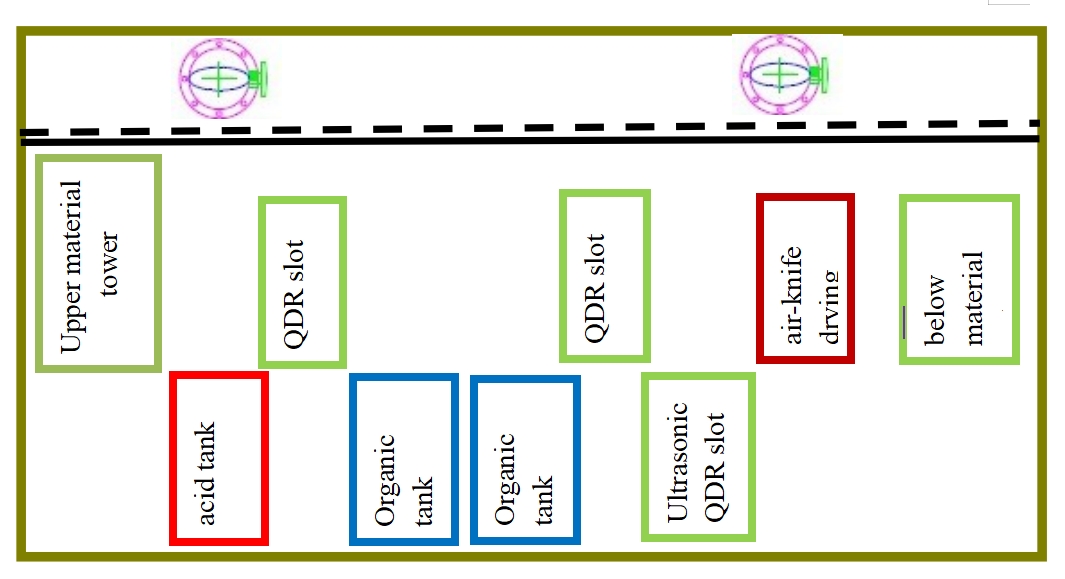

1 # Acid washing -2 # Ultrasonic water washing -3 # Organic washing -4 # Organic washing -5 # Ultrasonic water washing -6 # Ultrasonic water washing -7 # Wind knife

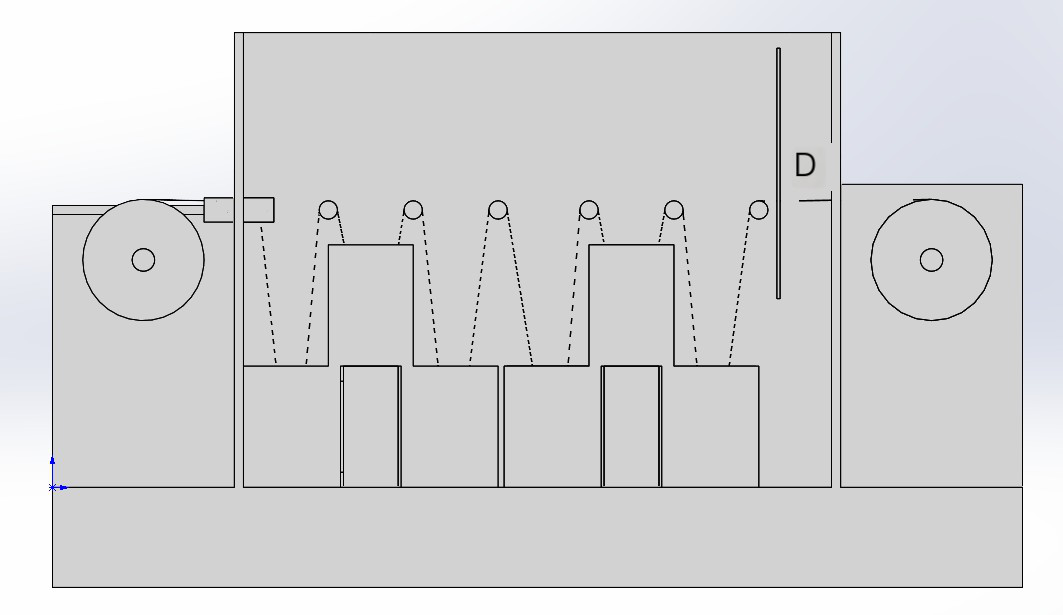

2.2 Outline Structure Diagram:

2.3 The table layout is as follows

2.4 Process parameters for each slot:

|

production processes |

Auxiliary functions |

Time (S) |

Temperature (℃) |

material |

Slot cover |

heater |

convulsions |

|

|

1 |

acid pickling |

Immersion liquid ultrasound |

0-9999 |

RT |

PVDF |

Manual slot cover (full slot cover) |

not have |

have |

|

2 |

QDR ultrasonic |

Immersion in ultrasonic solution |

0-9999 |

RT |

PVDF |

Manual slot cover (full slot cover) |

not have |

have |

|

3 |

organic |

Immersion liquid ultrasound |

0-9999 |

RT |

PVDF |

Manual slot cover (full slot cover) |

not have |

have |

|

4 |

QDR ultrasonic |

Immersion in ultrasonic solution |

0-9999 |

RT |

PVDF |

Manual slot cover (full slot cover) |

not have |

have |

2.5 Pickling tank (1 #)

|

medium |

acid liquor |

|

function |

Water immersion, liquid injection, ultrasound |

|

Tank material |

PVDF |

|

Tank size |

L300mm*W400mm*H400mm |

|

Usage temperature |

RT |

|

Liquid inlet method |

Manual liquid inlet |

|

water feeding pattern |

Automatic water intake |

|

Bubble method |

not have |

|

Liquid level method |

Connecting pipe liquid level |

|

Drainage method |

Circulating pump discharge |

|

Slot cover method |

Manual slot cover (full slot cover) |

2.6 Organic tank (3 # 4 #)

|

medium |

organic liquid |

|

function |

Water injection immersion jet ultrasound |

|

Tank material |

PVDF |

|

Tank size |

L300mm*W400mm*H400mm |

|

Usage temperature |

RT |

|

Liquid inlet method |

Manual liquid inlet |

|

water feeding pattern |

Automatic water intake |

|

Liquid level method |

Connecting pipe liquid level |

|

Drainage method |

Circulating pump discharge |

|

Slot cover method |

Manual slot cover |

2.7 QDR slot (2 # 5 #)

|

medium |

DIW |

|

function |

Immersion in water with ultrasonic jet |

|

Tank material |

PVDF |

|

Tank size |

L300mm*W400mm*H400mm |

|

Usage temperature |

RT |

|

Ultrasonic method |

Bottom ultrasonic frequency 40KHZ |

|

Liquid level method |

Connecting pipe liquid level |

|

Spray method |

not have |

|

Liquid inlet method |

Automatic water intake |

|

Drainage method |

Circulating pump discharge |

2.8 Ultrasonic QDR slot (6 #)

|

function |

Immersion in water with ultrasonic jet |

|

Tank material |

PVDF |

|

Tank size |

L300mm*W400mm*H400mm |

|

Usage temperature |

RT |

|

Ultrasonic method |

Right side ultrasound with a frequency of 40KHZ |

|

Liquid level method |

Connecting pipe liquid level |

|

Bubble method |

not have |

|

Spray method |

not have |

|

Liquid inlet method |

Automatic water intake |

|

Drainage method |

Circulating pump discharge |

2.9 Wind knife drying (8 #)

|

function |

350 long CDA air knife for drying |

|

Usage temperature |

RT70 (temperature adjustable (RT (0-150)) |

|

dynamic conditions |

Pressure 0.5-0.8mpa, gas consumption 1.3m ³/min |

|

material |

304 (surface polishing, removing burrs and burrs) |

3. Electrical components

3.1 Electrical box section

|

Electrical box section |

Equipped with an independent power distribution area, |

|

The equipment is equipped with a ventilation system to ensure air circulation inside the electrical box and has good heat dissipation function |

|

|

All electrical control systems are equipped with leakage protectors, reliable grounding devices, and emergency shutdown and alarm systems; |

3.2 Control section

|

controller |

The equipment is divided into automatic and manual parts during use. No other operations can be performed during automatic operation. In case of any problems, please press the emergency stop device. When the emergency stop is pressed, all work will be suspended. It is strictly prohibited to perform manual operations during automatic operation; |

|

Human computer interface: adopting professional and advanced graphical user interface, easy to operate and master, capable of completing trajectory editing and modification according to needs. |

|

|

Basic functions: password verification login, security protection door protection, alarm and other security functions, storage functions such as process prescription, operation and maintenance records, etc |

|

|

Tank control: Each tank has a corresponding separate control panel on the upper part of the front plate |

|

|

Warning light, buzzer, emergency stop |

|

|

Touch screen function: There is a manual operation button for the device, which allows real-time monitoring of the equipment according to the pipeline diagram settings. Each tank is monitored for various functions, including pump and valve start and stop, alarm display, and alarm recording. |

|

|

Interface settings: various parameter settings, interfaces for management personnel, process personnel, operators, etc. |

|

|

All chemical tanks are equipped with capacitive level sensors to prevent pump idling |

|

|

Equipment power-off protection function, protecting against program failures caused by unexpected power outages; |

|

|

The equipment has an automatic alarm information recording system |

4. Equipment utility engineering conditions

4.1 Electric Power Conditions

|

voltage |

380V |

|

frequency |

50Hz |

|

Number of phases |

Three-phase five-wire system |

|

power |

12KW |

|

loop |

DC24V |

4.2 Gas dynamic conditions of drug solution

|

medium |

temperature |

material |

Pressure kgf/cm2 |

nature |

caliber |

Connection method |

|

liquid |

||||||

|

pure water |

RT |

PFA |

2.5-3 |

≥ 18 MB |

3/4*6 |

Direct insertion |

|

gas |

||||||

|

CDA |

RT |

PFA tube |

5-6 |

no oil |

Φ10*2 |

Direct insertion |

|

N2 |

RT |

PFA tube |

4-5 |

Purity ≥ 99.99% |

Φ10*3 |

Direct insertion |

|

emission |

||||||

|

waste water |

RT |

PP |

— |

— |

DN32*1 |

slipknot |

|

Exhaust emissions |

||||||

|

gas |

RT |

PP |

— |

— |

Φ200*2 |

flange |

5. List of main materials for equipment

|

Serial Number |

name |

quantity |

Specification and model |

Supplier manufacturer |

|

1 |

skeleton |

1 |

40 * 40 (3mm thick) |

domestic |

|

2 |

casing |

1 |

Porcelain white PP10mm |

domestic |

|

3 |

Transparent observation doors and windows |

2 |

5mm |

South Asia |

|

4 |

Foot accessories |

4 |

M22 |

domestic |

|

5 |

Liquid level sensor |

4 |

Omron Japan |

|

|

6 |

solenoid valve |

6 |

2-position 3-way/straight through |

SMC |

|

7 |

Pipelines and valves |

10 |

DN25/DN40 PP/PFA |

GF/CKD |

|

8 |

PLC controlling sYstem |

1 |

Wistron |

|

|

9 |

Touch Screen |

1 |

10” |

Wistron |

|

10 |

Air switch, contactor |

6 |

schneider |

|

|

11 |

relay |

5 |

schneider |

6. Manufacturing cycle

60 working days after the prepayment of the effective subject matter of the contract is received;

We guarantee that we will not outsource the production and processing of all equipment for your company;

7. Equipment delivery inspection and transportation

Reviews

There are no reviews yet.